Engineering & Integration

Count on us for experience, knowledge and skills.

From design to implementation

Your power and control systems are critical in the success of your company. You can rely on our team to design, engineer, build and integrate complex power and control systems to make your operation run faster and more efficiently.

As part of the Tri-City Electric Co. family, we are uniquely positioned to provide you with a wide variety of technical expertise, capabilities, systems engineering and program management skills.

When you partner with Tri-City Electric Co., you can count on Confidence Delivered®.

Downloadable Brochures

Market expertise

Tri-City has a long history of providing engineering and integration services across a wide range of industries. You can count on our team to have the market expertise you’re looking for.

- Agricultural

- Automotive

- Cement & aggregates

- Chemical

- Food & beverage

- Government

- Glass

- Machine tool

- Metals

- Oil & gas

- Paper

- Printing

- Renewable energy

- Tire & rubber

- Utilities

- Water treatment

A team you can trust.

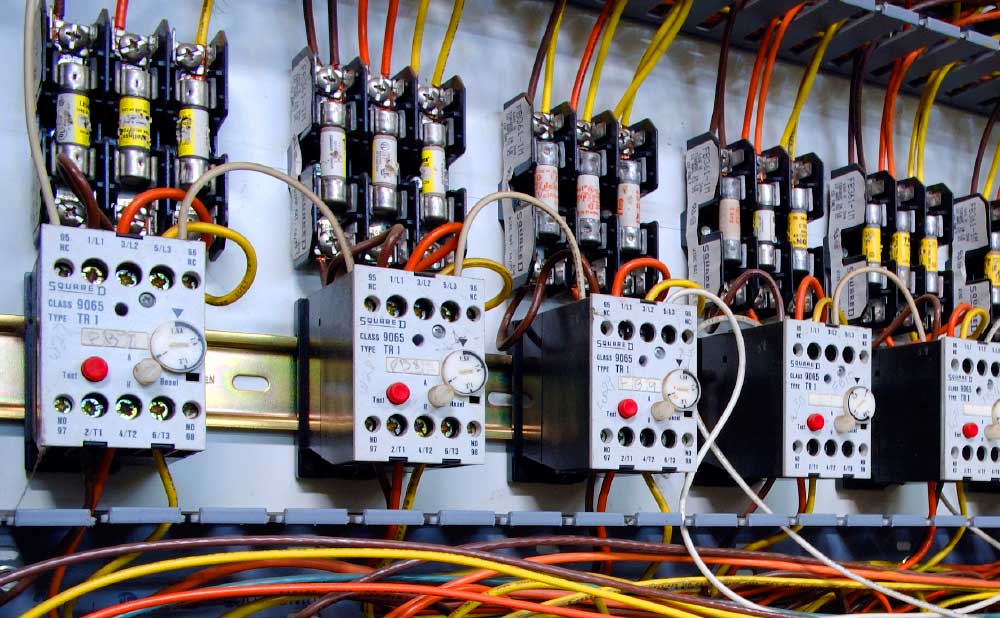

When you partner with Tri-City Electric Co., you get the knowledge, quality and responsive service that comes with a team with over 500 years of combined experience. Tri-City Electric Co.’s Engineering and Integration division has in-depth knowledge and experience in designing, building and integrating complex power distribution applications.

Areas of expertise

Power system analysis and design

- Power metering and monitoring solutions

- Protective relay design, settings & programming

- Energy management automation

- Power system documentation

- Low & medium voltage equipment

- Specification & evaluation

Click + to expand Power system analysis and design items below:

Industrial/Commercial system design

Tri-City Electric. Co. can provide complete electrical engineering design services for new construction, expansion, and major renovation projects. We can also develop project engineer and construction.

Short-circuit and coordination analysis

Short-Circuit analysis calculates the magnitude of prospective fault currents throughout the power system. These calculations determine the minimum required interrupting and withstand ratings for power distribution equipment.

The short-circuit analysis provides information to coordinate protective devices setting and ensure a balance of selective fault clearing and equipment protection. Tri-City Electric Co. can perform short-circuit analysis using complex-impedance, ANSI or IEC calculation methodologies.

Load flow analysis

Load flow analysis evaluates the performance of the power system during steady-state operating conditions. This can calculate power system losses, optimal transformer tap settings, and capacitor sizing and location for numerous operating configurations and contingencies. It is a valuable tool for planning system expansion and equipment loading.

Arc-flash hazard analysis & mitigation

Arc-flash hazard analysis is an important part of any organization’s electrical safety program. The analysis determines the flash protection boundary distance and PPE required to perform work on energized equipment. Application of arcflash hazard warning labels to equipment enables compliance with OSHA and NEC requirements. Tri-City Electric Co. can provide hazard mitigation and avoidance designs to reduce exposure to arcing fault hazards.

Utility & industrial system protection

Tri-City Electric Co. can provide engineering services to determine relay and breaker protection settings and control schemes for electromechanical and microprocessor based systems. We can assist with comprehensive protection system documentation and relay system functional test design.

Industrial SCADA design

SCADA systems provide system operators and engineers with centralized supervision and control of the power distribution system. SCADA systems can provide a degree of automation for switching operations, load shedding, and cogeneration control. Tri-City Electric Co. can design and install SCADA systems utilizing a variety of control and network protocols.

Renewable energy systems

Renewable energy systems can reduce utility service cost and dependence as well as influence a positive public image. Tri-City Electric Co. can specify, design, and coordinate installation of electric renewable energy technologies.

Power quality solutions

Power quality problems cause nuisance tripping, equipment heating, and inefficient system operation. Tri-City Electric Co. has the expertise to investigate and identify the cause of power quality problems, and to design solutions to return the system to maximum efficiency. We offer:

- Power system documentation

- Low & medium voltage equipment

- Specification & evaluation

Automation & control systems

- Design & functional specification

- Machine/Process control upgrades

- Project engineering & management

PLC/PAC programming & configuration

- Allen-Bradley, Siemens, GE, Schneider

- Legacy PLC upgrades & conversions

Motor control

- Variable frequency drives

- Motion/Servo Control

- MCC/IEC/NEMA motor starters

Industrial networking

- Ethernet, wireless ethernet, ControlNet, DeviceNet, Remote I/O, DH Profibus

Control System Documentation

- AutoCAD Computer Design, BIM

- Electrical Schematics

- Enclosure Layouts

- Operation/Maintenance Manuals

Operator interface design & programming

- Allen-Bradley, GE, Siemens

- FactoryTalk, RSView, GE iFix, Wonderware, VB, .Net

- Database Interface

- FactoryTalk Energy Metrix

- Schneider StruxureWare Power Monitoring Expert

Machine vision & bar code

- Design, configure, program

- Cognex, Keyence

Control panel design & fabrication

- Power distribution enclosures

- PLC enclosures

- Operator interface consoles

- Motor control center customization

- UL listed panel shop

Installation & commissioning support

- Installation specifications

- Cable/Conduit schedules

- Project management, construction supervision

- Troubleshooting & maintenance support services

- Lockout/tagout coordination

Operator/maintenance training

- Customized and on-site

Process control & instrumentation systems

- SCADA Systems

- Burner Management Systems

- Pneumatic Control Systems

- Distributed Control Systems (DCS) and all peripherals

- Programmable Controllers

- PC Networking and Telemetry

- Autonomous Digital Control Systems

- Calibration and Certification Services

Process control expertise

- Combustion

- Distillation

- Chemical

- Gas turbine generators

- Steam turbines

- Hydro electric

- Water purification

Process/Machine Safety

- Upgrades

- Analysis

- TÜV Certified

Burner Management

- Tuning

- Annual Testing

- MACT Certification

- Upgrades

Sensor & instrumentation applications

- Process control

- Instrumentation configuration & maintenance

Unique experience

- Cycle time reduction

- Reliability improvement

- Wireless technology (sensors, I/O, communication)

Safety

Our commitment to safety is uncompromising. It is a basic tenet of our operations and something that each employee must commit to before they can join our team.

Led by our in-house safety director and our team of safety professionals, our leadership team takes direct responsibility for employee safety and the quality of our safety programs. Foremen are accountable for the jobs and the people they supervise. Employees take responsibility for their own safety and the safety of their fellow workers.

Our safety initiatives include:

- Correcting potentially unsafe conditions and equipment before they produce injuries.

- Identifying unsafe or incorrect employee work habits and correcting them.

- Training and motivating all employees to work in a safe and conscientious manner.

- Pre-planning jobs to comply with safety standards.

As a result of these efforts, Tri-City Electric Co. has exceptionally low insurance modification rates over the last decade – a cost savings we proudly pass along to customers.